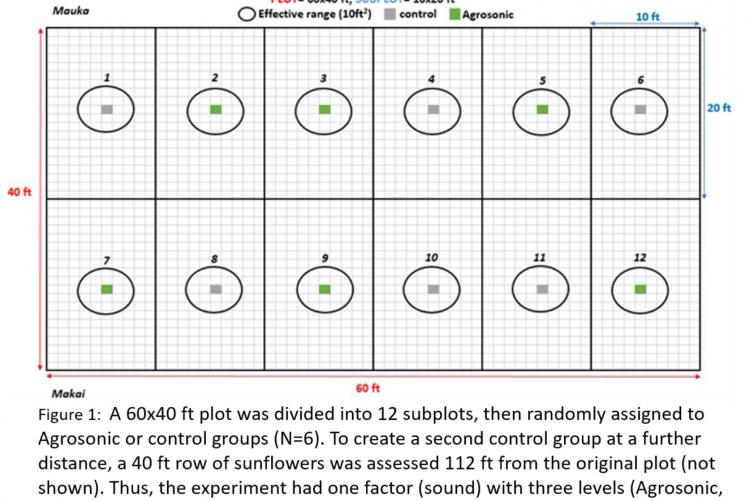

The AgroSonic is a proprietary device that emits a periodic, high-frequency sound designed to stimulate plant growth. Agrosonic was utilized to observe and quantify the growth and yield of sunflower cropsoveraneight-weekperiodonthePacificBiodieselFarmsofMaui,HI. Theexperimentwasdesigned to test 12 subplots with and without the Agrosonic device to quantify the effects of periodic sound on plant growth and yield over an 8-week period (Figure 1). The subplots for Agrosonic (green squares) and Controls (gray squares) were randomized throughout the 40 x 60 ft plot. Within each subplot, all the sunflower heights were measured within the Area of Effect (AoE, ~10 ft2).

Results Indicate Agrosonic Improves Sunflower Crop Height and Yield at Time of Harvest.

Sunflower development and assessment of AgroSonics treatment to increase the production of biofuels.

Pacific Biodiesel sowed Daytona sunflowers with 8 inch spacing (18,000 plants per acre) and the experiment was initiated 16 days after sowing. A 60 x 40 ft plot was divided into 12 subplots, then randomly assigned to Agrosonic or control groups (N=6). To create a second control group at a further distance, a 40 ft row of sunflowers was assessed 112 ft from the original plot. Thus, the experiment had one factor (sound) with three levels (Agrosonic, control_10 ft, control_112ft). The AgroSonic area of effect (AoE) was approximated to be 10 ft . For each replicate, all plants within the AoE were assessed (technical replicates ranged from 2-8 plants), which were then averaged for analysis. For Control_10 ft, flags were placed at 10 ft distance from Agrosonic and all plants within a 10ft2 area of the flag were assessed (technical replicates ranged from 3-7 plants), which were then averaged for analysis. For Control_112 ft, a single 40 ft row of plants were assessed with 4 plants averaged per replicate (roughly equates to density of plants within 10 ft2 area). Plants were assessed weekly with three response variables: plant height, growth stage, and sunflower diameter. Growth stage was quantified by using a sunflower growth key published by the North Dakota State University Extension Office. Sunflowers were harvested during week 8 of the experiment (crop was 10 weeks after sowing). ANOVA with Tukey’s HSD was used to examine differences between treatment groups.

Sunflower height:

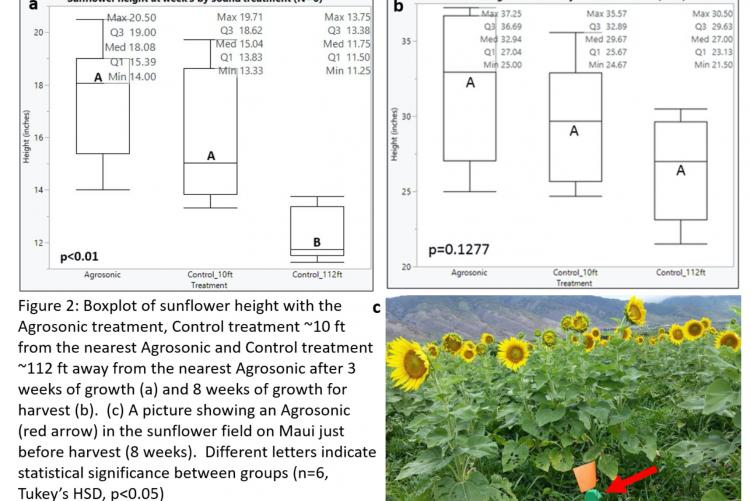

As early as week three of Agrosonic exposure the sunflowers begin to demonstrate significant differences in height between the Agrosonic treatment group and the control group located 112 ft from the Agrosonic devices (Figure 2a). The results show that the median height of Agrosonic treated sunflowers was 18 in. while the median height of the control group located approximately 10 ft from the Agrosonic device had a median height of 15 in. The 112 ft control group was significantly different from both the Agrosonic treatment and the 10 ft control group with a median height of 11.75 in. After eight weeks of Agrosonic exposure, differences in plant height were nearing statistical significance between the three groups (p=0.1277) illustrating an inverse relationship between median sunflower height and distance from the Agrosonic (Figure 2b). The median height for sunflowers exposed to Agrosonic for 8 weeks was 33 in. while the median height of sunflowers within the 10 ft control group was 29 in. The control group samples 112 ft away from an Agrosonic had a median height of 27 in.

Sunflower head diameter:

At time of harvest (eight weeks of Agrosonic exposure), the diameter of the sunflower heads was measured in all three groups. After eight weeks of Agrosonic exposure, there was a statistically significant difference in sunflower head diameter between the 112 ft control group and the Agrosonic treatment group as well as the 10 ft control group (p=0.001, Figure 3). The median head diameter for sunflowers exposed to Agrosonic for 8 weeks was 4 in. while the median head diameter of sunflowers within the 10 ft control group was 3.45 in. The control group samples 112 ft away from an Agrosonic had a median head diameter of 2.5 in.

Discussion:

The experiment performed at the Pacific Biodiesel Farms demonstrates that Agrosonic has a positive effect on sunflower height as well as the head diameter at time of harvest. While not statistically significant, the sunflower height within the Agrosonic treatment group was 11% taller than the control group located 10 ft away from the Agrosonic device and 22% taller than the sunflowers located 112 ft away from Agrosonic after 8 weeks of Agrosonic exposure. Thus, it appears that there is a gradual decline in sunflower height as the plants become more distant from the Agrosonic device. The difference in height of the sunflowers at harvest shows a clear trend and nears statistical significance (p=0.1277). This effect on sunflower growth appears to be more pronounced in the earlier stages of growth (3 weeks exposure) with the Agrosonic sunflowers being 20% and 54% taller than the 10 ft control group and the 112 ft control group, respectively, after 3 weeks of Agrosonic exposure (p<0.01). This result suggests that the Agrosonic device may increase the growth rate of the sunflower plant at earlier stages which may allow it to reach maturity earlier than expected. Interestingly, at the time of harvest, the effects of Agrosonic may be more significant with the sunflower head diameter being 16% and 60% wider than the 10 ft control group and the 112 ft control group, respectively, after 8 weeks of Agrosonic exposure (p<0.001). In order to optimize yield of sunflower biodiesel production, the sunflower head surface area (seed content) is the most important factor to consider. This experiment has shown that sunflowers within the Agrosonic treatment group have a head surface area of 12.5 in2 representing a 34% and 155% increase in surface area over the 10 ft control group and the 112 ft control group, respectively (Figure 4, left). Furthermore, there is a strong correlation (R2=0.692) between sunflower plant height and head diameter (Figure 4, right). Thus, Agrosonic may increase plant growth rate, height, seed production and biodiesel production when compared to the control groups within this experiment.

Conclusion:

This experiment has demonstrated that Agrosonic significantly increases the height and head diameter of sunflowers when compared to distant sunflowers in the 112 ft control group. While not statistically significant, there is a clear increase in sunflower height and head diameter between the Agrosonic treatment and the 10 ft control treatment. The lack of statistical significance may be a result of the Agrosonic also influencing the control group located 10 ft away from the Agrosonic treatment group. Additional experiments are being performed to assess the Area of Influence (AoI) of Agrosonic to better understand the required device distribution throughout a crop to optimize growth, yield and Agrosonic placement. Most importantly, this experiment demonstrated that Agrosonic significantly increases the sunflower head diameter by 60% resulting in 155% more surface area when compared to the control group located 112 ft from the Agrosonic device. Thus, utilizing Agrosonic may increase yield and biodiesel production by greater than 100% per sunflower head. Additional experiments are ongoing to corroborate these findings and quantify the AoI of the Agrosonic device.